Digiquartz® Advantage

Leader

Paroscientific is the leader in the field of high-accuracy pressure measurement.

Paroscientific is the leader in the field of high-accuracy pressure measurement.

Precision comparable to the best primary standards is achieved through the use of a special quartz crystal resonator whose frequency of oscillation varies with pressure-induced stress. A quartz crystal temperature signal is provided to thermally compensate the calculated pressure and achieve high accuracy over a wide range of temperatures.

Digiquartz® Pressure Instrumentation

Paroscientific manufactures and sells a complete line of high-precision pressure instrumentation. Resolution of up to one part-per-billion of full scale and typical accuracy of 0.01% of full scale are achieved even under difficult environmental conditions. Other desirable characteristics include high reliability, low power consumption, and excellent long-term stability.

Over 30 full scale pressure ranges are available – from a fraction of an atmosphere to thousands of atmospheres (+/-2 psig to 40,000 psia). Absolute and gauge transducers have been packaged in a variety of configurations including intelligent transmitters, depth sensors, laboratory and portable standards, meteorological measurement systems and water level systems. Intelligent electronics have two-way digital interfaces that allow the user to adjust sample rates, resolution, engineering units and other operational parameters.

Digiquartz® products are successfully used in such diverse fields as metrology, oceanography, meteorology, process control, aerospace, energy exploration and laboratory instrumentation.

Advantages of Digital Technology

The use of digital pressure transducers has grown dramatically with the trend towards digital data-acquisition and control systems. Inherently digital sensors such as frequency output devices have been combined with microprocessor based systems to provide unparalleled accuracy and performance, even under extreme environmental conditions. The design and performance requirements of these advanced transducers include:

- Digital output

- Accuracy comparable to primary standards

- Highly reliable and simple design

- Insensitivity to environmental factors

- Minimum size, weight and power consumption

- Ease and utility of readout

True digital sensors have a great advantage in resolution and accuracy over traditional analog devices because more precise measurements can be made in the time domain. Digital-type signals are also less susceptible to interference, easier to transmit over long distances, and readily interface to counter-timers, telemetry and digital computer systems.

Performance

Digiquartz® pressure products are the highest resolution, lowest noise, and most accurate instruments available today. The transducers are based on the inherently digital, highly stable, vibrating quartz crystal technology developed by Paroscientific over the last four decades. They are designed and tested to deliver outstanding performance even under difficult field conditions. Although many applications require both high resolution and accuracy, short-term measurements generally benefit from our high pressure sensitivity while longer term measurements need our accuracy, stability, and insensitivity to environmental errors.

- High Resolution

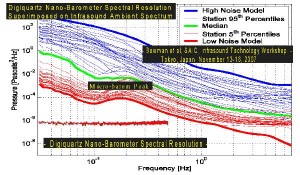

With a sensor of inadequate resolution, real signals can be obscured by noise, or sensor noise can be interpreted as real signals.

Paroscientific transducer mechanisms, oscillator circuits, and digital interfaces are carefully designed for ultra-high resolution.

Resolution of up to one part-per-billion is available with Paroscientific intelligent products. Applications where it is important

to measure extremely small pressure changes include; tsunami detection, sea-floor subsidence, infrasound, GPS Meteorology, leak-rate testing,

wind shear, wake-turbulence, detecting tornadoes and earthquakes.

With a sensor of inadequate resolution, real signals can be obscured by noise, or sensor noise can be interpreted as real signals.

Paroscientific transducer mechanisms, oscillator circuits, and digital interfaces are carefully designed for ultra-high resolution.

Resolution of up to one part-per-billion is available with Paroscientific intelligent products. Applications where it is important

to measure extremely small pressure changes include; tsunami detection, sea-floor subsidence, infrasound, GPS Meteorology, leak-rate testing,

wind shear, wake-turbulence, detecting tornadoes and earthquakes.

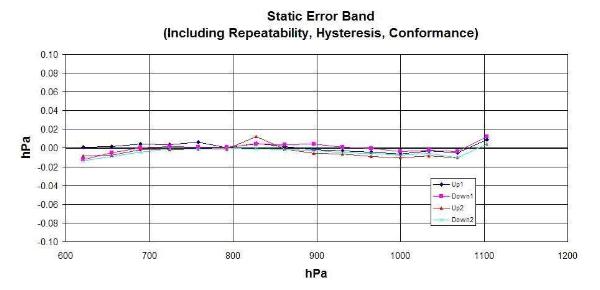

- Static Error Band

Typical accuracy of Digiquartz® Instruments is 0.01% of full scale or better. Accuracy relative to the primary standard includes resolution, hysteresis, non-repeatability and non-conformance. Digiquartz® Instruments are calibrated across a wide operating temperature and accuracy does not degrade as temperature changes.

Typical static error band for Digiquartz® Instruments is achieved after meticulous testing and calibration. Calibration is performed by

applying known pressure from primary standards to manifolds of transducers mounted in temperature chambers. Two frequency (or period) output

signals are sent from each transducer. Pressure is measured with a force-sensitive quartz crystal whose output period changes with applied load.

A second period output comes from a quartz crystal temperature sensor used for thermal compensation. The manifold of transducer signals are

multiplexed, measured, and the data fit to derive coefficients for the standard equation that characterizes the transducers. The calibration

coefficients are provided with each transducer and the indicated pressure (calculated) will agree with the “true” applied pressure with a

typical accuracy of 0.01 percent of transducer full scale over the full operational range of pressure and temperatures. Digiquartz® Intelligent

Transmitters store the calibration coefficients in non-volatile EEPROM to provide fully temperature-compensated and linearized outputs on the

bi-directional RS-232 and RS-485 interfaces.

Typical static error band for Digiquartz® Instruments is achieved after meticulous testing and calibration. Calibration is performed by

applying known pressure from primary standards to manifolds of transducers mounted in temperature chambers. Two frequency (or period) output

signals are sent from each transducer. Pressure is measured with a force-sensitive quartz crystal whose output period changes with applied load.

A second period output comes from a quartz crystal temperature sensor used for thermal compensation. The manifold of transducer signals are

multiplexed, measured, and the data fit to derive coefficients for the standard equation that characterizes the transducers. The calibration

coefficients are provided with each transducer and the indicated pressure (calculated) will agree with the “true” applied pressure with a

typical accuracy of 0.01 percent of transducer full scale over the full operational range of pressure and temperatures. Digiquartz® Intelligent

Transmitters store the calibration coefficients in non-volatile EEPROM to provide fully temperature-compensated and linearized outputs on the

bi-directional RS-232 and RS-485 interfaces.

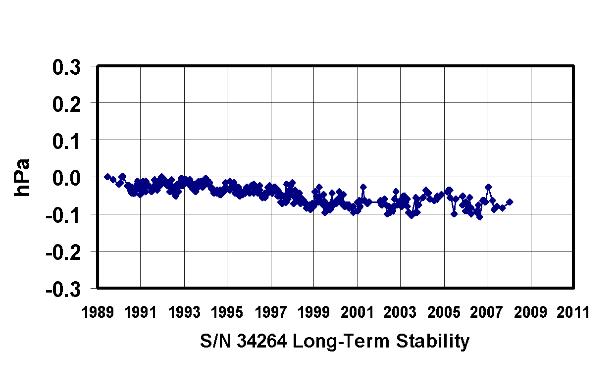

- Long-Term Stability

Long-term stability generates repeatable and reliable measurements that reduce the maintenance and operational cost of applications and instruments.

Paroscientific has an ongoing long-term stability test of three Digiquartz barometers. Measurements on these instruments indicate that the median

drift rate of the units tested is -0.007 hPa (-0.0002 inHg or 7 parts-per-million) per year over the nineteen-year test period.

Paroscientific has an ongoing long-term stability test of three Digiquartz barometers. Measurements on these instruments indicate that the median

drift rate of the units tested is -0.007 hPa (-0.0002 inHg or 7 parts-per-million) per year over the nineteen-year test period.

- Environmentally Rugged and Reliable

Digiquartz® Instruments are carefully calibrated and temperature-compensated over a broad temperature range. They are also designed to survive extremes of shock and vibration with accurate, reliable measurements. Paroscientific transducers have been used in a variety of applications from deep space probes to ocean bottom deployments. All Digiquartz transducers have an internal quartz temperature sensor whose output is used to thermally compensate the calculated pressure and achieve high accuracy over a wide range of temperatures.

- Low Cost of Ownership

Digiquartz® products provide a low total-cost-of-ownership. The long-term stability of Digiquartz® products reduces recalibration intervals and operational costs. Ease of use reduces the need for extensive training. Reliable operation eliminates excessive product purchases, repair costs and loss of revenues due to process interruptions.

Warranties, Service and Support

Paroscientific Inc. provides world-class products, service and quality. We offer a 5-year limited warranty on all of our pressure transducers including a 3-year stability warranty on all barometric products and a free 2-year zero adjustment with a calibration certificate traceable to NIST on all absolute pressure instruments ( < 1000 psia).

Quality Assurance and Test

Paroscientific, Inc., maintains a Quality Management System that is certified to the requirements of the ISO 9001 International Quality Standard. All calibrations performed at Paroscientific, Inc. are traceable to the National Institute of Standards and Technology (N.I.S.T.) Documented quality and test procedures provide consistency in our products and processes from design and development through production, calibration, test, and servicing. Our quality system and commitment to excellence ensure our customers of outstanding products and services.